Last updated: 3rd December 2024

Wiper Motor Restoration

I recently stripped down some old 6-volt and 12-volt wiper motors to rebuild them. Apart from tinkering with wiper motors in the past, I have not given them close attention.

As

with most used Austin Seven parts, they were all seized to a certain

extent. I took out all the drive gears to just leave the motor in place

so I could still run the wiper. I then noticed two ‘tubes’ that are part

of the wiper case casting. These tubes both run from the centre of the

wiper shaft to the outside of the case. Both tubes then have a small

oiler that has a small ball bearing in the end. These oilers, when

encrusted with dirt and paint, look like an old rivet or screw. Have a

look at the pictures to see what I mean.

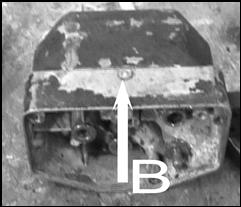

The picture above shows the inside of the case with the motor drive

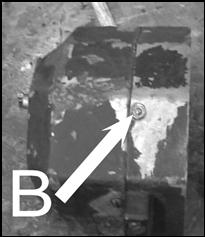

gear “A” and the two tubes “B”. The two pictures below show where the

oilers are located, both marked “B”.

Maybe there are two oilers so that the wiper can be fitted either way

up, or is it to allow the oil to be put in the top oiler, and then open

up the bottom oiler to encourage the oil to run down the tube?

The two pictures below show where the oilers are located, both marked “B”. Maybe there are two oilers so that the wiper can be fitted either way up, or is it to allow the oil to be put in the top oiler, and then open up the bottom oiler to encourage the oil to run down the tube?

Once these old units had been cleaned and oiled they all ran perfectly.

This article, written by Lee Webster, originally appeared in CA7C Seven Focus in Apr 2007 p20.

See also:

Wiper Motor Adjustment

DW3 Wiper Motor Improvements

Windscreen Wiper Maintenance