Last updated: 3rd December 2024

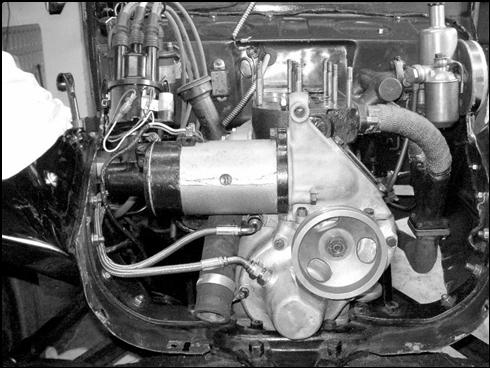

Crankshaft Conversion 1½" (pressurised)

I have fitted a 1½" pressurised crankshaft in my Austin Seven. The conversion, I believe is very similar to the one that Austin would have fitted to your new Nippy or early Speedy, at extra cost. (Ulsters had an pressurized 15/16" crankshaft).

I hope this

will be a useful guide if anybody else wishes to carry out a similar conversion

in the future.

I would

recommend that you have suitable good original parts to work with as you do not

wish these bits to let you down. Any special engine modifications that I have

not listed amongst my parts I will leave to you to source but for example you

may wish to consider a high lift camshaft, large inlet valves, double springs,

high compression head, change of carburettor or over bored block, just to name a

few bits.

As you will

see this is not a five minute job and you will need access to some machining,

but the end result is very satisfying and I now run with a 50~70 psi oil

pressure on the big end bearings, Combine this with the larger crankshaft

journals makes the bottom end very strong and quite indestructible.

There are a few questions that I have been asked, and may be helpful;

Q1. What did it cost?

I estimate that the parts costs alone has been the wrong side of £1750.00, if

you require to have block bored and a host of special bits then it’s just going

to be more.

Q2. Was it worth it?

No! but for me it’s a yes (if that makes sense!)

Q3. Why did I do it?

I have always

wanted a pressurized engine so for me this justifies it. The 1½" crankshafts are

virtually indestructible and this is a big attraction for me. This now gives a

engine capability of 6000 RPM (normal engines do not like much above 4500 rpm)

not that I am planning going to these limits. One other major point to consider

for me was I have had and known several incidents when the little end bolts have

failed in these little engines with catastrophic results and I feel this is a

very weak point. The Phoenix , Renault or original Nippy con-rods do not use

these bolt, these having a fully floating gudgeon pin in the piston like most

modern engines.

Q4. When should it this engine be considered?

I would strongly recommend that this type of engine is fitted, if you plan to

push your engine hard (the racing clan would not contemplate using anything

else) as the damage a broken crankshaft can cause at high speed is not worth

thinking about.

Q5. What would you do different?

Well I am still waiting for the new timing cover to be finished to accept a

starting handle. other than that not a lot. If you wish to go down this route

feel free to contact me.

Parts required: 1 x Phoenix Crankshaft; 4 x Phoenix Con-rods; 1 x Phoenix Nose piece; 1 x Set of shell bearings; 1 x Front timing cover; 1 x Set of front and rear bearings; 1 x Set Camshaft rollers; 1 x High pressure Oil pump; 1 x Relief valve; 1x Oils filter+ housing; 1 x Set of oil pipes and fittings; 1 x Complete gasket set; 1 x Rear seal cover; 1 x Set of tab washers; 1 x Set + 1 extra block to crankcase studs; 1 x Aluminium deep sump; 1 x Relief valve spring and ball; 1 x Small high pressure oil gauge; 1 x Set of new pistons [optional] or a set floating Gudgeon pins; 1 x Set of steel timing Gears [optional]

Parts to be modified:

Crankcase

1]. Oil jets remove and blanked, I copied the original jets but without the holes in the middle, I locktited them in for good measure.

2]. Camshaft location bolt removed and drilled to accept a 5/16" diameter hole.

Camshaft

1] Front bronze bush oil hole reduced to 3/32" size (using a 6 mm brass bolt as a plug) External ‘O' rings were fitted to outside of the bush to reduce oil loss. Modification to the bolt location to accept the additional block stud.

2] Rear bronze bush oil turned through 180 degrees and re-drilled with 3/32" and a new chamfer added.

Small parts:

New oil pump housing machined to suit sump/housing.

New timing cover made to fit housing and chassis.

Flywheel assembly, con-rods and pistons balanced.

Sump also required some machining to suit new oil pump.

This article, written by Mike Davies, originally appeared in CA7C Seven Focus in Mar 2006 pp16-17.

See also:

Every Piston Tells a Story

Front Main Bearing Retaining Lip

Gearbox Oil Seals

Good Sump Joints

Little End Bolt Failure

Overhauling the Gearbox

Replacing a 3-speed gearbox with 4-speed

Synchromesh Set-up