Last updated: 3rd December 2024

How it Works - Carburettors (part 2)

After losing many of you with the theory of how the Zenith side draught carburettor works, I will deal with the specific details of the 26VA version fitted to the Austin Seven.

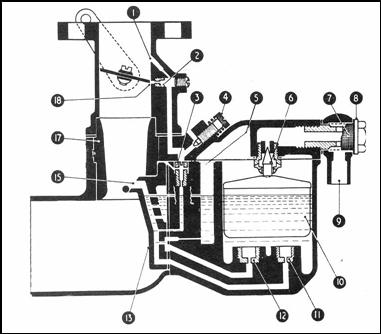

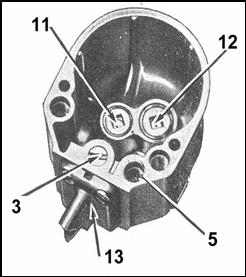

Unfortunately because of the design of the side draught version it is impossible to portray the three-dimensional carburettor as a two-dimensional drawing so the picture below is of an up draught version of the same carburettor. If you look carefully you will recognised the float bowl and emulsion block layout as identical to the Austin Seven carburettor, the only real difference is the layout of the slow running air regulation screw and passages although the actual working of this section of the carburettor shown is identical to the 26VA used on Austin Seven's.

1 slow running outlet

2 Progression jet 3 Slow running jet

4 Air regulation screw

5 Capacity Tube 6 Fuel float needle

valve 7 Fuel Filter

8 Fuel Inlet bolt

9 Fuel inlet connection 10 Float

11 Main Jet 12 Compensating Jet

13 Emulsion block 15 Emulsion block

beak 17 Choke tube

18 Progression jet outlet

As you will see all the features are there but some in different positions!

In

normal running the main

jet (11) is doing

most of the work supplying a flow of petrol, relying on the ‘suction’ from the

engine. The level of fuel in the float bowl is such that the emulsion block

beak (15) is just above the fuel

level which means that fuel should not flow out until lifted out by the

flow of air past the beak (15) Immediately you will see from this that if the

fuel level is too

high in the float bowl not only will it drip out it will also provide too rich a mixture when the

engine is running. Conversely if the level is too low then the amount of fuel

lifted by the flow

of air through the choke tube will be less leading to a weak mixture. The

correct way

to adjust the fuel

level is by

altering the thickness of the aluminium washer between the fuel float needle valve (6) and the

body of the carburettor.

In

normal running the main

jet (11) is doing

most of the work supplying a flow of petrol, relying on the ‘suction’ from the

engine. The level of fuel in the float bowl is such that the emulsion block

beak (15) is just above the fuel

level which means that fuel should not flow out until lifted out by the

flow of air past the beak (15) Immediately you will see from this that if the

fuel level is too

high in the float bowl not only will it drip out it will also provide too rich a mixture when the

engine is running. Conversely if the level is too low then the amount of fuel

lifted by the flow

of air through the choke tube will be less leading to a weak mixture. The

correct way

to adjust the fuel

level is by

altering the thickness of the aluminium washer between the fuel float needle valve (6) and the

body of the carburettor.

When the throttle is first opened the air flowing into the engine is initially slow and causes less petrol than required to enter the air stream, therefore the compensating jet (12), capacity tube (5) and the three minute holes in the emulsion block all contribute to provide extra fuel, temporarily making the mixture more rich until the air flow is more constant and the flow from the main jet is sufficient.

We now turn to one of the most misunderstood parts of the carburettor, the slow running jet (3) and air regulation screw (4).

The amount of fuel to achieve slow running is controlled by the slow

running jet (3). The air flow in the slow running system is controlled

by the air regulation screw (4). If you screw the adjustment in more air

is being sucked from the engine side of the system which in turn lifts

more fuel from the jet (3), making the mixture richer. If you unscrew

the control then more air from the outside is sucked in, less from the

engine therefore less fuel is lifted from the jet (3) making the mixture

weaker.

Now the misunderstood part! If you look at the engine side of the slow

running passage-way you will see it has two branches, one finishes near

the engine, the slow running outlet (1), the other finishes at the

butterfly. When the butterfly is closed (or virtually closed) there is

more ’suck’ on the engine side of it than on the carburettor side

therefore the engine sucks through slow running outlet (1), making it

work at its most efficient lifting fuel from the slow running jet. When

the butterfly is open then the pressure (or amount of ’suck’) is the

same on both sides of the butterfly and in both of the two passages

therefore the ’suck’ hardly exists and the slow running jet is no longer

actively providing fuel. The slow running adjustment, therefore, only

works when the throttle is closed, it has no effect on the mixture when

the throttle is open, or substantially open.

In normal use the carburettor should give you very little trouble,

however, due to the design of the jets in the float bowl any

condensation or dirt can very easily block the main or the compensating

jets in the bottom of the float bowl. These are simply unscrewed (using

one of the bowl fixing screws which should have a square key end) and

cleared by blowing through, do not use a wire unless absolutely forced

to. Don’t forget to make sure that water or dirt is not in the

passageways under the jets. These can be cleared by blowing down through

the emulsion block beak. If you cover the other jet holes then most of

your blow will come through the open hole.

If you find the slow running adjustment is doing nothing then under the

carburettor you will find a little brass plug screw which, when removed,

will reveal a jet, the progression jet (2) which is most likely blocked.

Other than the throttle stop screw which sets tick-over speed there are

no adjustments designed into the carburettor. However, if you have a

modified engine then adjustment may be necessary by changing the size of

the main jet.

This article, written by Malcolm Watts, originally appeared in Seven Focus Jan 2007 pp13-15.