Home

Page

welcome to our website

About Us

information about our Club

Contacts

our Officers and Committee

Events Diary

our events for the

months ahead

Event Reports

from the last four months

Member's Cars

a selection of

our active "Sevens"

Joys of being a 7'er

and a few stories

Do you fancy an Austin Seven?

advice on buying a "Seven"

Photo Gallery

of our past activities and

"Sevens" in close up

From the Past

Items from 1920/30s

magazines

Registration Marks

in the UK from 1903

Help at the roadside

fuel and electrical problems

Austin Seven Journal

advice for Austin Agents

& Service Depots

Austin Seven

Handbooks

information for the

new owner

Technical Articles

our Members help you

with various tasks

Austin Big Seven

Sixlite & Forlite

Magazine Articles

relevant to Sevens

Road Tests

for the most popular "Sevens"

Parts and Services

sources of spares etc

Quick Tips

a few handy ideas

Other Articles

of interest, not technical

Austin Seven Books

some of the books available

A7CA and FBHVC

CA7C is an active supporter

Links to other Austin

Seven Sites

Website Policy

on advertisements and links

Last updated:

23 September, 2023

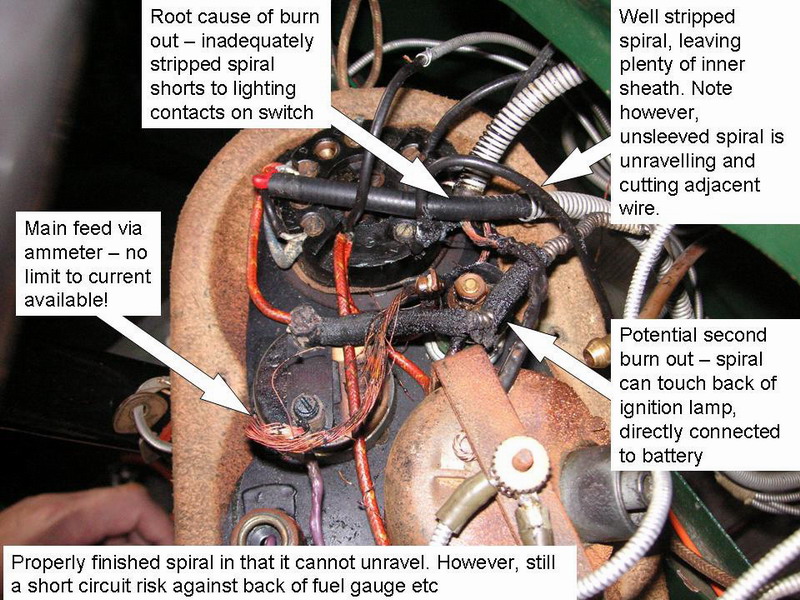

Armoured Wiring - unexpected hazards

We had spent the day ambling along the lanes and generally enjoying the sunshine. Later that day, and it was time to put on some lights, refuel both cars and drivers and plan the following day. It was at this point that life got far too interesting; one of the 'Sevens' started to fill up with smoke, as hot insulation dripped out from between the coils on the armoured covering of it’s cabling. A quick disconnection of the battery and a selective hotwiring allowed it to be driven back to base. Battery isolators are a “must have”!

In daylight, the extent of the damage could be seen. The main wire from the starter motor to the ammeter was molten, the wire from the ammeter to the main switch completely frazzled and serious damage had occurred to the feed to the rear lights.

This proved

to be the root cause of the problem. All of the car’s wiring had been installed

using armoured cabling. At the light switch, the wire for the taillights had had

very little armouring stripped back, and none of the inner sheathing was left to

protect the insulation. The razor sharp aluminium had cut through to the light

feed, and being earthed had short circuited the lighting circuit to earth.

A few very important observations regarding this type of cable:

- The outer armouring is an aluminium strip, which leaves very sharp edges when cut back. It is essential that the armouring is covered at the cut end either with a rubber sleeve or better still, some heat shrink sleeving. This also prevents it from unravelling.

- The inner sheathing protects the individual wires from the aluminium. This sheath should always be left slightly longer than the armouring so that it cannot cut through the insulation of the individual wires.

- The aluminium will be earthed simply by its touching the car body. Therefore it should always be removed or covered in the vicinity of terminations – the back of the instrument panel has a large number of them and the wires will inevitably jiggle about under vibration

My recommendations?

Well, if you wish to use this type of cable, then fine. However, I would

identify some fixed part of the car, such as inside the dash near the hole for

the wires to the cut out, there the armoured cable should be terminated. It

needs to be anchored down with P clips or a saddle clamp so that it can’t flap

about. Here, sleeve each cut end with heat-shrink sleeving after joining it to

a short length of the correct colour coded wire. If you want to put an in-line

connector to make removing the dash panel easier, then this is the obvious

place.

Under the

bonnet, inside the headlight shells etc again ensure that the spiral is secured

and bound so that it can’t touch a connection and can’t come unravelled –

especially if near something prone to vibration, such as the dynamo.

This article, written by Geoff Hardman, originally appeared in CA7C Seven Focus in Nov 2006 pp14-15.